Hot and Sweaty Red Friday

May 21st, 2010 . by CaryAs we break the 100 degree mark here in Phoenix, I naturally chose today as the day to start on one of the last paying wood jobs I have left. This one is a set of four (one double, two singles) custom wood frame screen doors for a Victorian era bungalow in the historic district for a friend of mine.

The start of the project is always full of promise and trepidation – did I buy enough wood? how about supplies? will the design work? did I measure it right? – but always promises an adventure.

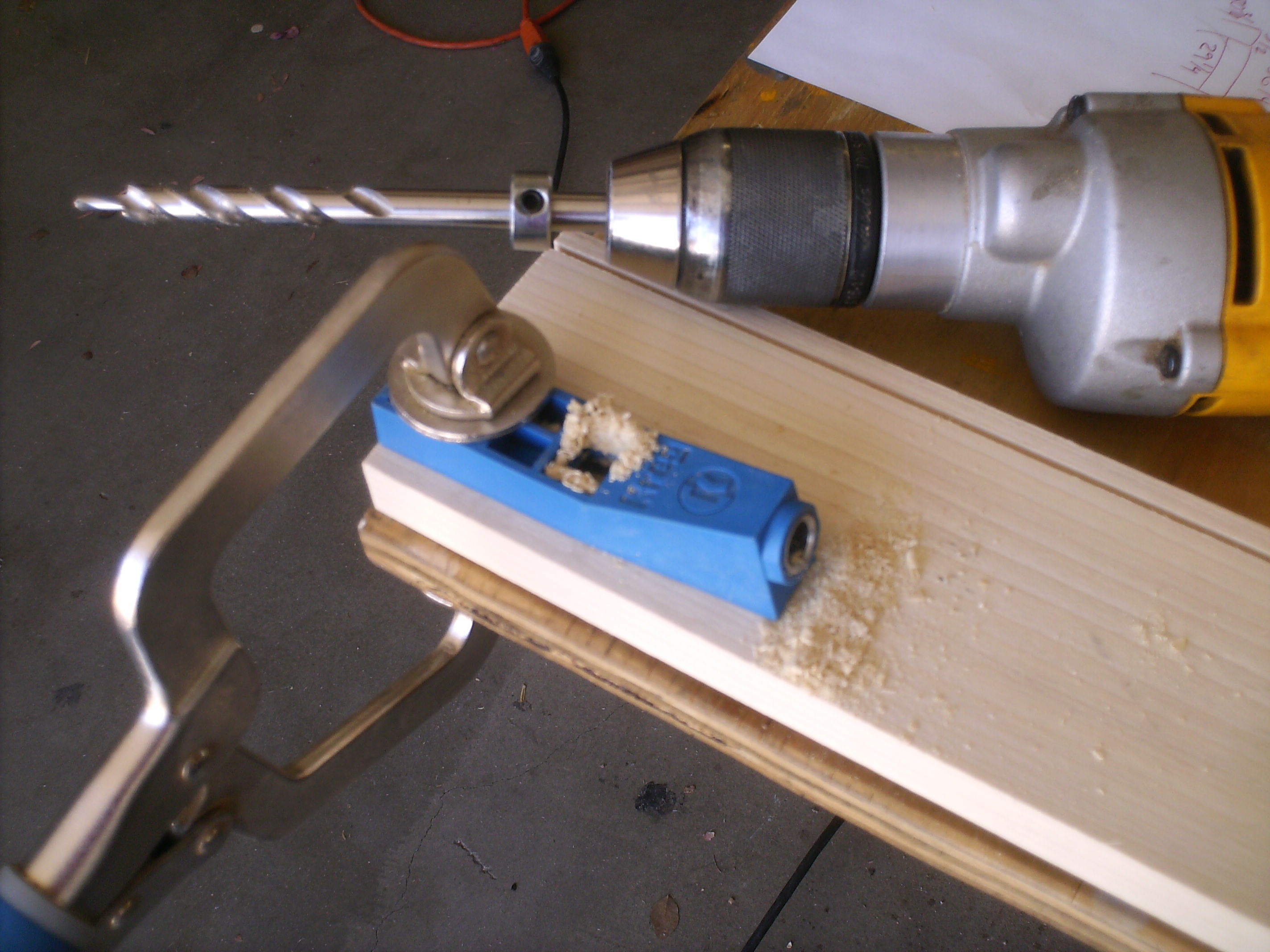

Once I got TMBWitW’s car out of my shop, I was able to start. The scariest part of any project is the milling – once everything is cut to length and any other cutting/hacking/shaping is completed, a big sigh of relief is heard. Since this is a pretty straight forward project, the sigh of relief comes early. Now the fun part – assembling the parts. The door frames are a simple four piece frame (there will be a middle strut installed later) so the best joinery trick is the most straightforward – pocket screws. I use a small Kreg jig that is actually designed for repair-in-place jobs. I have found that it’s versatility in repairs carries over to the bench work in the first place quite nicely.

That shot also shows the channel I cut for the screen spline to be applied later.

Didn’t know you were going to get a Kreg commercial in here, did you?

Next, the frames are assembled with the square-drive pocket screws. A little glue and the screws act as permanent clamps. With the pocket screw angled in, the fit is pretty much forever. With a high-use item such as these screen doors, I wanted to make sure the duty cycle lifetime would be on the higher side.

After the pocket screws are seated, and the frame is complete, I used plugs to fill the holes. Yes, repairs will be tricky, but the overall look is one of solidity.

Next step (probably Sunday afternoon) is to take a belt sander to the frames, ensuring smooth joints front and back and taking the filler plugs down to flush. After that will be a coat of primer and then the hardware. The screen material itself will be last – for the sharpest looking screens, avoid painting them or poking holes in them with tools!

(note to the sharper-eyed readers – yes, the plugs are oak. yes, the frames are paint grade poplar. the doors will be painted, remember? oak is stable enough to use as filler in the poplar frame. and, as a special treat for next time, i’ll show you the one milling mistake i made and how it will be repaired.)

Chat ya later…

Thank you for stopping by, In GOD We Trust, God bless you all, don’t buy or breed cats or dogs while homeless pets die (spay, neuter & adopt a pet, one by one, until there are none), Wear Red on Fridays, and support Warriors for Innocence!

Nice work. I like the fact that you used plugs. Some folks would just leave the holes!

I dig that jig…Rhyme not intended. I’m going to have to get me one of those.

Thanks, John. It’s the attention to detail that I think my customers appreciate the most.

A good beginning to what will surely be a great project!

I haven’t undertaken such a project in quite a while. My Unisaw is growing impatient sitting in the garage doubling as a table.

I have a Kreg Jig myself. Used them since the mid 90’s

Joe – I sure hope it turns out well. I have high hopes, anyway!

Gary – you should, once in a while, just build something for the fun of it. Unisaws can get cranky when not utilized on a regular basis. Ain’t Kreg’s the stuff?

Yeah, it’s the stuff alright. I met Kreg in the mid 90’s at the Sacramento Home and Garden Show. His fist pass at the jig was good enough to launch him into the world of high demand wood working tools.

The original jig was made of cast aluminum, and had a tendency to dull the outside of the step bits, but with care, it was no problem.

I have lots of projects on the ‘to do’ list, just very little time or revenue to support them. Hopefully soon.

[…] cavity needed to be redone) and I am making preparations to go to a friends house and install the screen doors that I built. I’ll take pictures and post them later, I […]